Titanium Grade 7

Grade 7 has very good weldability. Being substantially single phase material, the microstructure of the alpha phase is not affected greatly by thermal treatments or welding temperatures.Therefore, the mechanical properties of a correctly welded joint are equal to, or exceed those of the parent metal and show good ductility.

Titanium Grade 7 is a less common and specialized grade of titanium compared to Grade 2 or Grade 5. Grade 7 titanium is a corrosion-resistant alloy that contains a small amount of palladium. This addition of palladium enhances its resistance to corrosion in reducing and acidic environments. Here are some key characteristics and applications of Titanium Grade 7:

- Corrosion Resistance: Grade 7 titanium exhibits excellent resistance to corrosion, particularly in environments where chlorides are present, such as in brine solutions, seawater, and various acids. This makes it suitable for applications in the chemical and offshore industries.

- Palladium Addition: The small amount of palladium in Grade 7 (about 0.12-0.25%) improves its corrosion resistance, making it more robust in aggressive environments compared to other pure titanium grades.

- Biocompatibility: Like other titanium grades, Grade 7 is biocompatible and non-reactive within the human body. It can be used for certain medical and dental applications, such as dental implants and orthopedic devices.

- Heat Resistance: Grade 7 titanium can withstand high temperatures, making it suitable for use in heat exchangers and other equipment in high-temperature applications.

- Weldability: This grade of titanium is weldable, which is essential for many manufacturing processes and applications.

- Chemical Processing: Grade 7 is often used in equipment and components that come into contact with corrosive chemicals, as it has superior resistance to acidic and chloride-rich environments.

- Offshore and Marine: It is commonly used in offshore oil and gas applications, where exposure to seawater and brine solutions requires excellent corrosion resistance.

- Heat Exchangers: Used in the construction of heat exchangers and other heat transfer equipment due to its ability to withstand high temperatures and corrosive conditions.

- Medical: In certain medical applications where enhanced corrosion resistance is required, such as dental implants.

- Desalination: In desalination plants where titanium is used in the production of fresh water from seawater, Grade 7’s corrosion resistance is valuable.

- Sheet Plates –3mm – 8mm thickness

- Round Bars – 8mm – 250mm

- Wires –0.10mm to 6mm

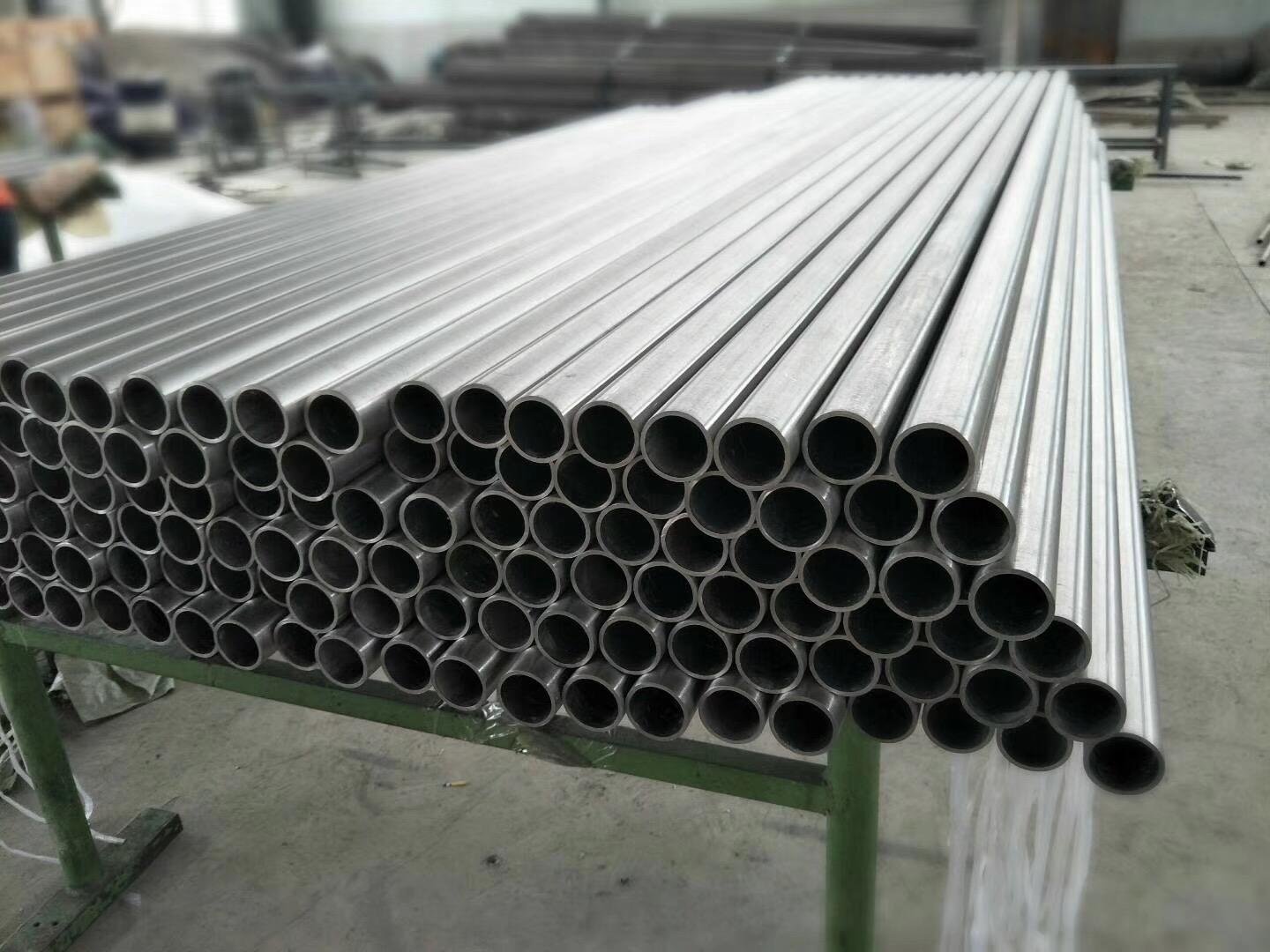

- Pipes –1/4 inch NB to 6 inch NB (Sch 10 and 40)

While Titanium Grade 7 is not as widely used as Grade 2 or Grade 5, it is highly specialized for applications that demand exceptional resistance to specific corrosive environments. Its ability to withstand chloride-rich and acidic conditions makes it valuable in industries like chemical processing, offshore, and desalination, where other materials may be vulnerable to corrosion.

Products and Size Ranges

We provide the following products and Size ranges:

We supply hardness of wire (Soft, Quater Hard, Half Hard) according to customer requirements.

Material Certification and Traceability

At Satyam Overseas, we prioritize Material Certification and Traceability. Our materials, meeting ASTM and ASME standards, come with 3.1 Mill Test Certificates as a guarantee of compliance. Additionally, upon request, we provide 3.2 Mill Test Certificates for added assurance. Every material is clearly marked and accompanied by a corresponding certificate, meticulously linking markings to certification. This meticulous approach ensures complete accountability and unwavering reliability throughout our supply chain.

Chemical Composition

| O | N | C | H | Fe | AI | V | Ni | Mo | Others | Residuals |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.20 | 0.05 | 0.08 | 0.015 | 0.40 | 5.5-6.75 | 3.5-4.5 | 0.4 |

Physical properties

| Melting point, ± 15 °C | 1650 °C |

|---|---|

| Density | 4.43 g/cm3 |

| Beta transus, ± 15 °C | 995 °C |

| Thermal expansion, 20 – 100 °C | 9.0 *10-6 K-1 |

| Thermal expansion, 0 – 300 °C | 9.5 *10-6 K-1 |

| Thermal conductivity, room temperature | 6.6 W/mK |

| Thermal conductivity, 400 °C | 13 W/mK |

| Specific heat, room temperature | 0.57 J/gK |

| Specific heat, 400 °C | 0.65 J/gK |

| Electrical resistivity, room temperature | 171 µW*cm |

| Poisson’s ratio | 0.30-0.33 |

Physical properties

| Forms | ASTM | ASME | DIN |

|---|---|---|---|

| Sheet and plate | B265 | - | - |

| Bars and billets | B348 | - | - |

| Castings | - | - | B367 |