Inconel 601 Round Bars & Wires

Inconel 601 Round Bars, which is a Nickel – Chromium alloy that offers good heat and corrosion resistance. The weld fillers developed for RA 602 can also provide a weld which is stronger and more oxidation resistant than Inconel 601 Square Bars base metal. Inconel 601 Flat Bars is a solid solution nickel chromium alloy for high temperature heat resistance. Inconel 601 Threaded Bars is either annealed at around 2000 Degree F or solution treated at around 2100 Degree F, both followed by air cooling. Chemical – processing applications for Inconel 601 Hollow Bars include process heaters, condenser tubes in sour – water strippers, and insulating cans in ammonia reformers. Thanks to this unique composition, Inconel 601 Hexagonal Bars is popular in a number of major global industries including: Pollution control, Power generation and Aerospace. Inconel 601 Triangular Bars is a Nickel – Chromium – iron corrosion and heat resistant alloy, which is often used for insulating cans in ammonia reformers and catalyst support grids used in nitric acid production. High – speed operations such as grinding, turning or milling, are performed in Inconel 601 Bars using water – based coolants. Inconel 601 Rods is a general – purpose engineering material for applications that require resistance to heat and corrosion. In addition, the weld products developed for RA 602 can provide a stronger weld with higher oxidation resistant than Inconel 601 Rods.

Specifications:

Inconel 601 Round Bars: Inconel 601 round bars are solid cylindrical metal bars made from Inconel 601 alloy. These bars are available in various diameters and lengths to suit different applications. They are often used in applications where high-temperature strength and corrosion resistance are essential, such as in the aerospace, chemical processing, and petrochemical industries.

- Key features of Inconel 601 round bars:

- High-temperature resistance: Inconel 601 can withstand elevated temperatures, making it suitable for use in high-temperature environments, including furnace and heat-treating applications.

- Corrosion resistance: This alloy exhibits excellent resistance to a wide range of corrosive environments, including acids, alkaline solutions, and oxidizing gases.

- Good mechanical properties: Inconel 601 round bars offer good mechanical strength and creep resistance.

- Excellent weldability: Inconel 601 can be welded using various methods, enhancing its versatility.

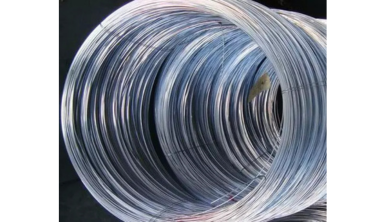

Inconel 601 Wires: Inconel 601 wires are thin, elongated metal strands made from Inconel 601 alloy. These wires are known for their flexibility and are commonly used in applications that require precision and high-temperature performance, such as electrical heating elements and thermocouples.

- Key features of Inconel 601 wires:

- HHigh-temperature stability: Inconel 601 wires can maintain their strength and resist oxidation at elevated temperatures, making them ideal for use in heating applications.

- Corrosion resistance: These wires can withstand aggressive chemical environments and are highly resistant to corrosion.

- Electrical conductivity: Inconel 601 wires exhibit good electrical conductivity, making them suitable for various electrical and heating applications.

- Ductility and formability: Inconel 601 wires can be easily shaped and formed to meet specific design requirements.

size range

We supply hardness of wire (Soft, Quater Hard, Half Hard) according to customer requirements.

Material Certification and Traceability

At Satyam Overseas, we prioritize Material Certification and Traceability. Our materials, meeting ASTM and ASME standards, come with 3.1 Mill Test Certificates as a guarantee of compliance. Additionally, upon request, we provide 3.2 Mill Test Certificates for added assurance. Every material is clearly marked and accompanied by a corresponding certificate, meticulously linking markings to certification. This meticulous approach ensures complete accountability and unwavering reliability throughout our supply chain.

Chemical Composition

| Ni | Cr | Fe | AI | C | Mn | S | Si | Cu | |

|---|---|---|---|---|---|---|---|---|---|

| Min | 58 | 21 | - | 1 | 0.03 | - | - | - | - |

| Max | 63 | 25 | 18 | 1.7 | 0.1 | 1 | 0.015 | 0.5 | 0.5 |

Physical Composition

| Density | Melting range | Relative magnetic permeability at 20 °C (68 °F) | Curie temperature |

|---|---|---|---|

| 8.05 g/cm3 (0.29 lb/in3 ) | 1,330-1,370 °C (2,426-2,498 °F) | 1.01 (Maximum) | -196 °C (Maximum) (-320.8 °F) |

Designations & Standards

| Forms | ASTM | ASME | DIN |

|---|---|---|---|

| 601 Round Bars | B 168 | SB 168 | 17742 17750 |

Differences between Inconel and Hastelloy

Inconel and Hastelloy are both nickel-chromium-molybdenum-based alloys. They are all corrosion-resistant and extremely strong metals. Hastelloy has greater molybdenum content than Inconel, although Inconel has a higher chromium concentration. This sets them apart in terms of corrosion resistance in different situations.