Titanium Grade 5

Titanium Grade 5 (titanium-aluminium-vanadium alloy) is among the most widely used alpha-beta titanium alloys, amounting to 50% of total titanium used globally. One of the prominent properties of Titanium Grade 5 is that it is entirely heat treatable, and can be used for temperatures up to 400°C. It combines low density (4.43 kg/dm) with outstanding corrosion resistance and good mechanical strength. Titanium Grade 5 has excellent tensile properties at room temperature and has a good creep resistance up to 300°C. It also exhibits excellent resistance against crack propagation and fatigue. The age-hardening ability of Titanium Grade 5 makes it a perfect choice for various applications, including fasteners and springs. It has a wide range of industrial applications due to its good machinability and weldability.

Titanium Grade 5, also known as Ti-6Al-4V, is one of the most commonly used titanium alloys. It is a popular choice in various industries due to its exceptional combination of strength, corrosion resistance, and low density. Here are some key characteristics and applications of Titanium Grade 5:

- Strength: Grade 5 titanium is known for its high strength-to-weight ratio. It is significantly stronger than commercially pure titanium (Grade 2) while still maintaining a relatively low density.

- Corrosion Resistance: This alloy exhibits excellent corrosion resistance, making it suitable for use in aggressive environments, such as marine, chemical, and aerospace applications.

- Low Density: Like all titanium alloys, Grade 5 titanium has a low density, which makes it a lightweight material. This is particularly valuable in industries where weight reduction is critical, such as aerospace and automotive.

- Biocompatibility: Titanium Grade 5 is biocompatible and non-reactive within the human body, which makes it suitable for medical implants, including bone plates, screws, and dental implants.

- Heat Resistance: It can withstand high temperatures, making it suitable for applications in the aerospace and automotive industries.

- Weldability: Grade 5 titanium is weldable, allowing it to be used in various manufacturing processes and applications.

- Versatility: Its versatile nature means it can be used in various industries, ranging from aerospace and medical to automotive and marine applications.

- Aerospace: Used in aircraft components, including airframes, engine parts, and landing gear, where its strength-to-weight ratio is highly advantageous.

- Medical:Commonly used for surgical implants, prosthetic devices, and dental applications due to its biocompatibility and strength.

- Automotive: Employed in high-performance automotive components, such as exhaust systems, suspension parts, and lightweight structural components.

- Marine: Used in marine applications due to its corrosion resistance, particularly for components exposed to seawater.

- Sports Equipment: Titanium Grade 5 is used in the manufacture of sports equipment like bicycle frames, golf club heads, and tennis rackets due to its strength and lightweight properties.

- Chemical Processing: Suitable for equipment that comes into contact with corrosive chemicals and high-temperature environments.

- Industrial Manufacturing: Utilized in various industrial applications where a combination of high strength, corrosion resistance, and lightweight properties is required.

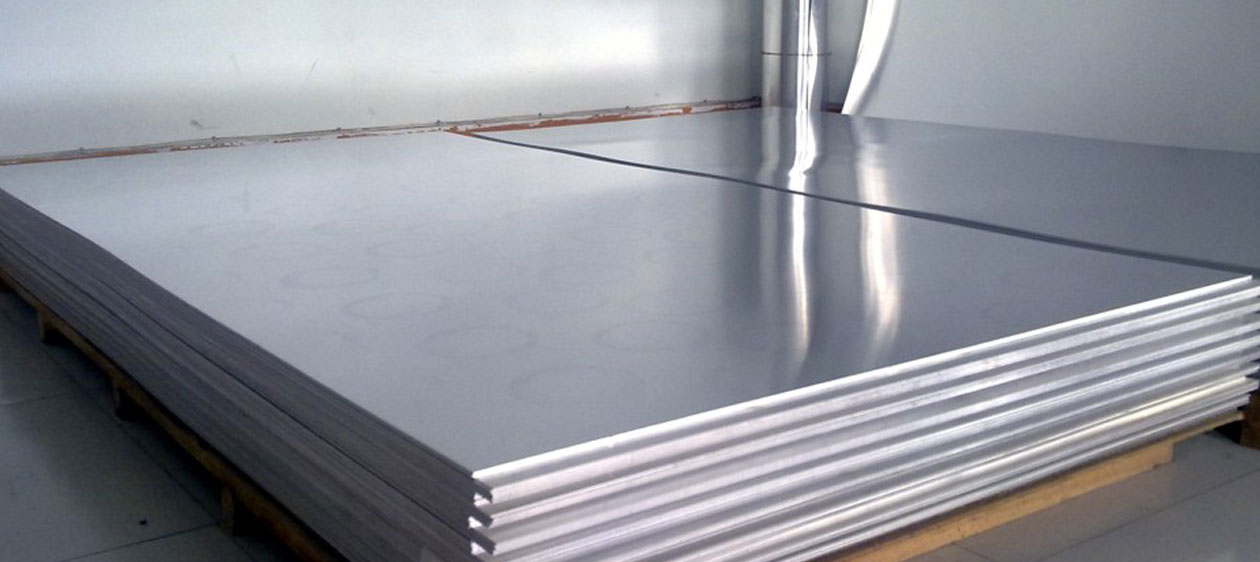

- Sheet Plates –3mm – 8mm thickness

- Round Bars – 8mm – 250mm

- Wires –0.10mm to 6mm

- Pipes –1/4 inch NB to 6 inch NB (Sch 10 and 40)

Overall, Titanium Grade 5 is a versatile and widely used titanium alloy, prized for its exceptional properties and its ability to perform in a broad range of demanding applications across different industries.

Products and Size Ranges

We provide the following products and Size ranges:

We supply hardness of wire (Soft, Quater Hard, Half Hard) according to customer requirements.

Material Certification and Traceability

At Satyam Overseas, we prioritize Material Certification and Traceability. Our materials, meeting ASTM and ASME standards, come with 3.1 Mill Test Certificates as a guarantee of compliance. Additionally, upon request, we provide 3.2 Mill Test Certificates for added assurance. Every material is clearly marked and accompanied by a corresponding certificate, meticulously linking markings to certification. This meticulous approach ensures complete accountability and unwavering reliability throughout our supply chain.

Chemical Composition

| O | N | C | H | Fe | AI | V | Ni | Mo | Others | Residuals |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.20 | 0.05 | 0.08 | 0.015 | 0.40 | 5.5-6.75 | 3.5-4.5 | 0.4 |

Physical properties

| Melting point, ± 15 °C | 1650 °C |

|---|---|

| Density | 4.43 g/cm3 |

| Beta transus, ± 15 °C | 995 °C |

| Thermal expansion, 20 – 100 °C | 9.0 *10-6 K-1 |

| Thermal expansion, 0 – 300 °C | 9.5 *10-6 K-1 |

| Thermal conductivity, room temperature | 6.6 W/mK |

| Thermal conductivity, 400 °C | 13 W/mK |

| Specific heat, room temperature | 0.57 J/gK |

| Specific heat, 400 °C | 0.65 J/gK |

| Electrical resistivity, room temperature | 171 µW*cm |

| Poisson’s ratio | 0.30-0.33 |

Physical properties

| Forms | ASTM | ASME | DIN |

|---|---|---|---|

| Sheet and plate | B265 | - | - |

| Bars and billets | B348 | - | - |

| Castings | - | - | B367 |